Spring steel, as an alloy steel used in the manufacture of various springs and other elastic components, plays a vital role in modern industries due to its remarkable strength, elasticity, workability, and weldability. The control of processing deformation in spring steel directly impacts the performance and lifespan of springs and other components. Therefore, effective measures must be taken to control processing deformation during the manufacturing of spring steel. In this article, let’s take a closer look at the control of processing deformation in spring steel.

Control of Processing Deformation in Spring Steel:

Firstly, in terms of material selection. The choice of raw material is crucial in the manufacturing process of spring steel, as it directly affects the performance and lifespan of springs and their elastic components. If the selected spring steel material has excessively high hardness, it is prone to fracture or deformation during use. Therefore, when selecting spring steel, it is essential to comprehensively consider its working environment and performance, opting for materials with good quality, uniform composition, and stable hardness to ensure excellent performance and long service life.

Secondly, in terms of design requirements. Rational design can reduce the risk of deformation during the processing of spring steel. For instance, optimizing the geometric shape and dimensions of parts to avoid sharp changes in cross-sections and sharp corners can lead to a more uniform stress distribution, thereby minimizing the possibility of deformation. Similarly, adopting symmetrical structures in structural design can balance forces and reduce deformation caused by uneven stress distribution.

Furthermore, in terms of cutting control. During the processing of spring steel, reasonable cutting control is crucial for ensuring dimensional accuracy and surface quality of workpieces. Factors such as cutting speed, feed rate, and cutting depth need to be considered when cutting spring steel. For example, appropriately increasing the cutting speed can reduce the temperature in the cutting area, minimize friction between the spring steel material and the cutting tool, and thus decrease the likelihood of deformation.

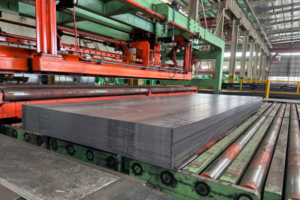

Additionally, in terms of forging processing. Forging, an essential metal processing method, enhances metal properties and quality by breaking up columnar grains, improving macrosegregation, and controlling grain size. During the processing of spring steel, unidirectional or bidirectional stretching can improve the surface quality and dimensional accuracy of spring steel, while reducing deformation during processing. Forging also enhances the elastic modulus and toughness, making spring steel materials more robust and durable.

Conclusion

In conclusion, to ensure that spring steel possesses sufficiently excellent performance and prevent deformation during processing, considerations must be given to material selection, design requirements, cutting control, and forging processing during the manufacturing process. These measures can effectively control deformation during the processing of spring steel, guaranteeing its performance and quality.

Why Choose Sino Special Metal?

Thank you for reading our article and we hope it can help you to have a better understanding of the control of processing deformation in spring steel. If you are looking for suppliers and manufacturers of stainless steel online now, we would advise you to visit Sino Special Metal.

As a leading supplier of spring steel from Shanghai China, Sino Special Metal offers customers high-quality 65Mn Spring Steel, 50CrV4 Spring Steel, 9260 Spring Steel, and SUP9 Spring Steel at a very competitive price.