O1 Tool Steel

O1 Tool Steel is an oil-hardening, general-purpose tool steel known for its good balance of toughness, wear resistance, and dimensional stability. It has a relatively high carbon and manganese content, which provides high hardness and abrasion resistance after heat treatment. O1 is easy to machine and has minimal distortion when oil-quenched, making it a popular choice for a range of tooling applications.

Please inquire now about your steel needs.

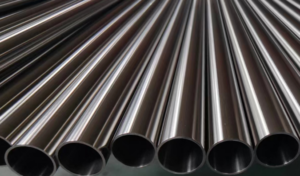

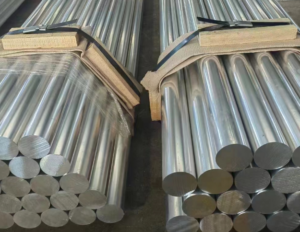

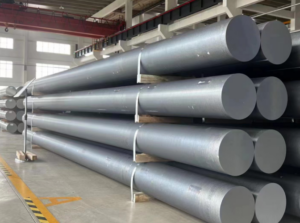

our O1 Tool Steel Supply: Available Forms and Sizes

| Form | Thickness / Diameter | Width | Length |

|---|---|---|---|

| O1 Tool Steel Sheets | 1 mm – 25 mm | 300 mm – 1200 mm | 1000 mm – 3000 mm |

| O1 Tool Steel Plates | 10 mm – 100 mm | 500 mm – 2000 mm | 1000 mm – 6000 mm |

| O1 Tool Steel Round Bars | 5 mm – 300 mm diameter | N/A | 1000 mm – 6000 mm |

| O1 Tool Steel Flat Bars | 3 mm – 50 mm thickness | 20 mm – 400 mm | 1000 mm – 6000 mm |

| O1 Tool Steel Square Bars | 10 mm – 200 mm | 10 mm – 200 mm | 1000 mm – 3000 mm |

| O1 Tool Steel Blocks | Customizable thickness | Customizable | Customizable |

Sino-Specialmetal is a trusted and professional supplier of O1 Tool Steel, providing high-quality material tailored to meet diverse industry needs. Our commitment to quality ensures that every piece of O1 Tool Steel we supply meets rigorous standards for hardness, toughness, and dimensional stability. With customizable options in various forms and sizes, we support applications ranging from precision tooling to heavy-duty cutting. Sino-Specialmetal’s expertise and reliability make us a go-to source for industries requiring dependable and durable O1 Tool Steel for their critical operations.

O1 Tool Steel material properties datenblatt as below:

chemical composition of O1 Tool Steel

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.85 – 1.00 |

| Manganese (Mn) | 1.00 – 1.40 |

| Chromium (Cr) | 0.40 – 0.60 |

| Tungsten (W) | 0.50 |

| Vanadium (V) | 0.30 |

| Silicon (Si) | 0.20 – 0.50 |

| Phosphorus (P) | 0.03 max |

| Sulfur (S) | 0.03 max |

Physical Properties of O1 Tool Steel

| Physical Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Thermal Expansion | 11.2 x 10⁻⁶ /°C (20-100°C) |

| Thermal Conductivity | 23.5 W/m·K at 20°C |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity | 0.42 x 10⁻⁶ Ω·m |

| Melting Point | 1,440°C |

Mechanical Properties of O1 Tool Steel

| Mechanical Property | Value |

|---|---|

| Hardness (Rockwell) | 57 – 63 HRC (after heat treatment) |

| Tensile Strength | Approximately 1,580 MPa |

| Yield Strength | Approximately 1,380 MPa |

| Modulus of Elasticity | 190 – 210 GPa |

| Impact Toughness | Moderate (suitable for general-purpose tooling) |

| Compressive Strength | High (resists deformation under load) |

Applications of O1 Tool Steel:

- Punches and Dies: Used in precision punching and forming due to its toughness and wear resistance.

- Blades and Knives: Ideal for custom knives, cutting tools, and industrial blades, offering good edge retention.

- Molds and Tooling Inserts: Suitable for mold inserts and die components in low-stress applications.

- Gauges and Fixtures: Excellent for precision gauges and fixtures, where dimensional stability is essential.

- Reamers and Broaches: Commonly used in reamers and broaches for its machinability and hardness.

O1 Tool Steel’s balance of hardness, toughness, and machinability makes it suitable for various general-purpose and precision tooling applications.

Different Designations for O1 Tool Steel:

| Standard | Designation |

|---|---|

| UNS | T31501 |

| AISI/SAE | O1 |

| DIN | 1.2510 |

| JIS | SKS3 |

| ISO | 100MnCrW4 |

| BS | BO1 |

| EN | 100MnCrW4 |

Fabrication and Heat Treatment of O1 Tool Steel:

Fabrication

- Machining: O1 Tool Steel is relatively easy to machine in its annealed state, making it suitable for precision machining tasks. Carbide-tipped tools are often recommended for improved tool life and accuracy.

- Grinding: Precision grinding is typically performed on O1 Tool Steel after hardening to achieve specific dimensions and finishes.

- Welding: Due to the high carbon content, welding is challenging and generally not recommended. If welding is required, preheating and post-weld heat treatment are necessary to minimize cracking.

Heat Treatment

Annealing:

- Heat O1 Tool Steel to 730-760°C, hold for 1-2 hours, then cool slowly in the furnace at a rate of no more than 10°C per hour until it reaches approximately 500°C, followed by air cooling. This process produces a hardness of around 200 HB (Brinell Hardness), making it easier for machining.

Stress Relieving:

- To relieve machining stresses, heat to 600-650°C, hold for 1-2 hours, then air cool. This step helps minimize distortion during further heat treatment.

Hardening:

- Preheat to 450-500°C, then increase to the austenitizing temperature of 780-800°C, ensuring the material reaches a uniform temperature. Quench in oil to achieve maximum hardness and minimal distortion.

Tempering:

- After hardening, temper immediately by heating to 150-230°C for a balance of hardness and toughness. Typical tempering cycles involve holding for 1 hour per inch of thickness, cooling to room temperature, and then re-tempering for applications requiring greater toughness and dimensional stability.

Key Considerations

O1 Tool Steel’s heat treatment processes, including hardening and tempering, are essential for maximizing hardness, wear resistance, and stability. Proper fabrication and heat treatment ensure the material’s suitability for precision tooling and general-purpose applications, balancing machinability with performance.

Contact us now! Free sample waiting for you.

Tel: +86-13012867759

Email: [email protected]

Tel: +86-021-54725826

Fax: +86-021-54717930