Spring steel sheets are a type of metal alloy that exhibit exceptional elastic properties, allowing them to be deformed significantly without breaking or suffering permanent damage. Their unique characteristics have made them indispensable in various industries, from automotive components to precision machinery. In this article, we delve deeper into the properties of spring steel sheets.

Properties of Spring Steel Sheets

Composition and Alloying Elements

Spring steel sheets are typically composed of carbon steel with the addition of elements like silicon, manganese, chromium, and nickel to enhance their mechanical properties. The carbon content in these alloys usually ranges from 0.5% to 1.5%, providing the necessary strength and ductility for spring applications. The alloying elements are added in specific proportions to optimize properties such as yield strength, tensile strength, fatigue resistance, and corrosion resistance.

Mechanical Properties

One of the defining characteristics of spring steel sheets is their high elastic limit, which allows them to undergo repeated deformation without losing their shape or functionality. This is achieved through a combination of their chemical composition and heat treatment processes. The yield strength of spring steel sheets is typically higher than that of regular carbon steel, ensuring that they can withstand significant loads without excessive deformation. Additionally, spring steel sheets exhibit good fatigue resistance, making them suitable for applications that involve cyclic loading.

Heat Treatment

The heat treatment process plays a crucial role in determining the final properties of spring steel sheets. The most common heat treatment techniques include quenching and tempering. Quenching involves rapidly cooling the steel from an elevated temperature to lock in the desired microstructure. Tempering is then performed to relieve internal stresses and improve toughness. The specific heat treatment parameters, such as temperature and time, are carefully controlled to achieve the desired balance between strength and ductility.

Surface Finish and Coatings

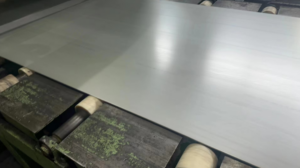

The surface finish of spring steel sheets is crucial for their performance and durability. A smooth, even finish minimizes stress concentrations and improves fatigue resistance. Various surface treatments, such as polishing, grinding, and shot peening, are employed to achieve the desired finish. Additionally, coatings like zinc phosphate or oil films may be applied to improve corrosion resistance and reduce friction.

Applications

Spring steel sheets find widespread applications across numerous industries. In the automotive sector, they are used in suspension systems, valve springs, and clutch components. In precision machinery, spring steel sheets are essential for making springs, levers, and other components that require high accuracy and repeatability. Other applications include aerospace, medical devices, and consumer electronics, where their exceptional mechanical properties and durability make them an ideal choice.

Processing Techniques

Processing spring steel sheets requires specialized techniques and equipment. Cold rolling is a common method used to achieve the desired thickness and flatness. Annealing processes are often employed to relieve internal stresses and improve machinability. Spring steel sheets can be cut, punched, and formed using conventional metalworking methods, but special considerations must be taken to prevent cracking or distortion during the process.

Conclusion

Spring steel sheets are a versatile material with exceptional elastic properties that make them indispensable in various applications. Their unique combination of strength, ductility, and fatigue resistance is achieved through careful alloy design and heat treatment processes.

If you are looking for spring steel sheet suppliers and manufacturers online now, we would advise you to visit Sino Special Metal. As a leading supplier of spring steel products from Shanghai China, Sino Special Metal offers customers high-quality spring steel, tool steel, and high-speed steel products at a very competitive price.