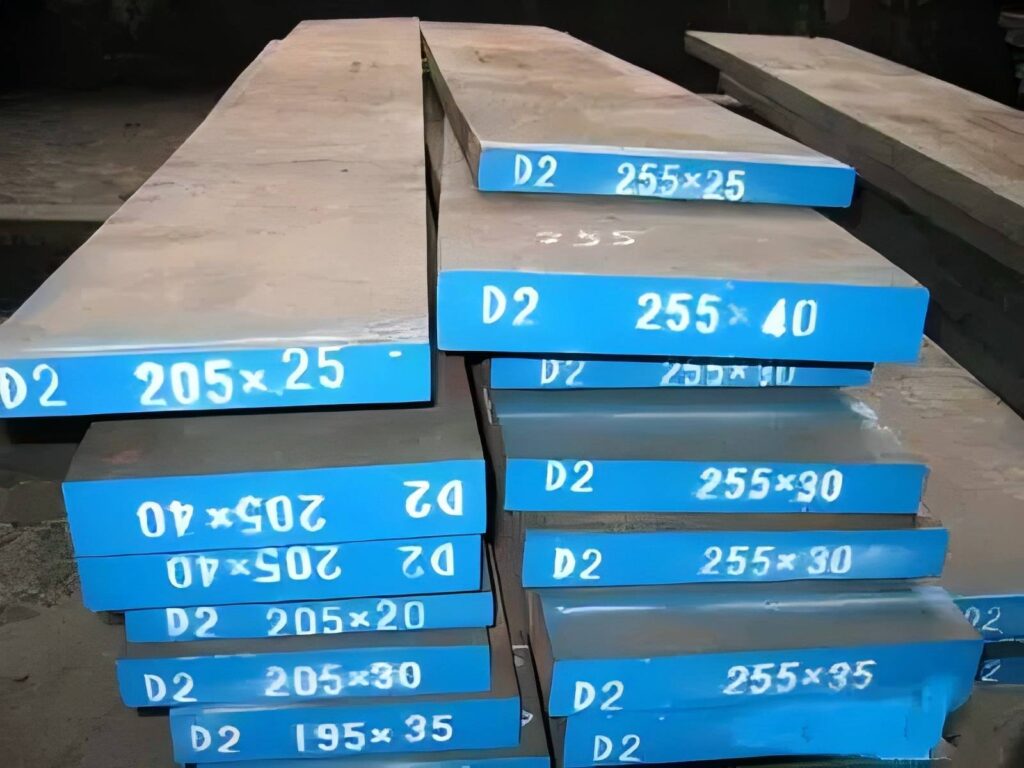

SAE-AISI D2 Tool Steel (T30402) Chromium Cold-Work Steel

D2 tool steel is a high-carbon, high-chromium, air-hardening tool steel widely known for its excellent wear resistance and toughness. This steel contains 1.5-2% carbon and 11-13% chromium, providing a strong carbide structure that significantly enhances its durability and wear resistance. Due to these properties, D2 is often utilized in manufacturing tools that require high precision and durability, such as cutting tools, dies, and punches.

Please inquire now about your steel needs.

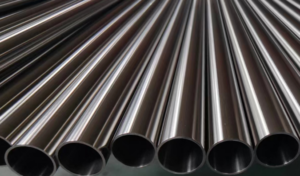

our D2 Tool Steel Supply: Available Forms and Sizes

| Form | Thickness / Diameter | Width | Length |

|---|---|---|---|

| D2 Tool Steel Sheets | 0.5 mm – 20 mm | 300 mm – 1200 mm | 1000 mm – 3000 mm |

| D2 Tool Steel Plates | 10 mm – 100 mm | 500 mm – 2000 mm | 1000 mm – 6000 mm |

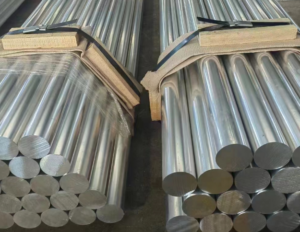

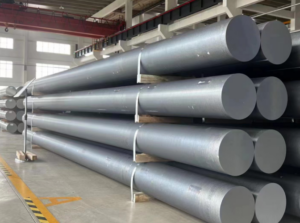

| D2 Tool Steel Round Bars | 10 mm – 500 mm diameter | – | 1000 mm – 6000 mm |

| D2 Tool Steel Flat Bars | 5 mm – 100 mm thickness | 20 mm – 500 mm | 1000 mm – 6000 mm |

| D2 Tool Steel Blocks | Customizable thickness | Customizable | Customizable |

| D2 Tool Steel Square Bars | 10 mm – 300 mm | 10 mm – 300 mm | 1000 mm – 6000 mm |

Notes:

- Custom Sizes: Custom dimensions may be available upon request based on manufacturing capabilities.

- Tolerance: Dimensional tolerances will vary based on specific requirements and standards.

- Heat Treatment: D2 tool steel can be delivered in annealed or pre-hardened conditions depending on application needs.

D2 Tool Steel material properties datenblatt as below:

chemical composition of D2 Tool Steel

| Element | Content (%) |

|---|---|

| Carbon (C) | 1.50 – 2.00 |

| Chromium (Cr) | 11.00 – 13.00 |

| Molybdenum (Mo) | 0.60 |

| Vanadium (V) | 0.30 |

| Manganese (Mn) | 0.60 |

| Silicon (Si) | 0.60 |

| Phosphorus (P) | 0.03 (max) |

| Sulfur (S) | 0.03 (max) |

Physical Properties of D2 Tool Steel

| Physical Property | Value |

|---|---|

| Density | 7.7 – 7.8 g/cm³ |

| Thermal Expansion | 10.4 x 10⁻⁶ /°C (20-100°C) |

| Thermal Conductivity | 20.3 W/m·K at 20°C |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity | 0.75 x 10⁻⁶ Ω·m |

| Melting Range | 1421 – 1454°C |

Mechanical Properties of D2 Tool Steel

| Mechanical Property | Value |

|---|---|

| Hardness (Rockwell) | 55 – 62 HRC (after heat treatment) |

| Tensile Strength | Up to 1,965 MPa (varies with treatment) |

| Yield Strength | Approximately 1,725 MPa |

| Compressive Strength | High, varies with heat treatment |

| Impact Toughness | Moderate (lower compared to other tool steels) |

| Modulus of Elasticity | 210 GPa |

| Elongation at Break | 5 – 6% (depends on treatment) |

Applications of D2 Tool Steel:

- Cutting Tools: Ideal for dies, punches, and blades due to high wear resistance.

- Forming Tools: Used in molds and forming dies for precision and durability.

- Industrial Knives: Suitable for industrial-grade blades requiring toughness.

- Cold Work Applications: Excellent for cold-forming and stamping operations.

- Shear Blades: Effective in shearing and trimming tools for metals and non-metals.

Different Designations for D2 Tool Steel:

| Standard | Designation |

|---|---|

| UNS | T30402 |

| AISI/SAE | D2 |

| DIN | 1.2379 |

| JIS | SKD11 |

| ISO | X153CrMoV12 |

| BS | BD2 |

| EN | X155CrVMo12-1 |

Fabrication and Heat Treatment of D2 Tool Steel:

Fabrication

- Machining: D2 tool steel is challenging to machine due to its high hardness. It is usually machined in an annealed state to reduce tool wear.

- Grinding: Suitable for grinding applications, which is often needed for achieving the final dimensions and surface finish.

- Welding: Difficult to weld due to high carbon content, and preheating and post-weld heat treatment are essential to avoid cracking.

- Forming: D2 can be formed, but its high strength makes it more challenging than other tool steels.

Heat Treatment

Annealing:

- Heat to 850-900°C, hold for 1-2 hours, and then cool slowly in the furnace at a rate of 10°C per hour until reaching approximately 600°C. Air cooling can be used thereafter.

Hardening:

- Preheat to 750-800°C, then heat to the austenitizing temperature of 980-1040°C. Hold at temperature and then quench in still air or oil, depending on the part size.

Tempering:

- After hardening, temper D2 at 150-540°C depending on the desired hardness. Multiple tempering cycles are often recommended to ensure dimensional stability.

Stress Relieving (optional):

- D2 may be stress relieved before hardening by heating to 600-700°C, holding for 1-2 hours, and air cooling.

Contact us now! Free sample waiting for you.

Tel: +86-13012867759

Email: [email protected]

Tel: +86-021-54725826

Fax: +86-021-54717930