SAE-AISI H13 Tool Steel (T20813) Chromium Hot-Work Steel

H13 Tool Steel is a chromium-molybdenum hot-work tool steel known for its excellent toughness, high wear resistance, and ability to withstand high temperatures. It has a balanced composition of chromium, molybdenum, and vanadium, providing it with good thermal conductivity and high resistance to thermal fatigue, making it ideal for hot-work applications.

Please inquire now about your steel needs.

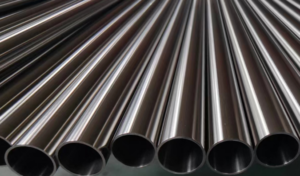

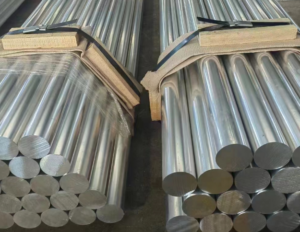

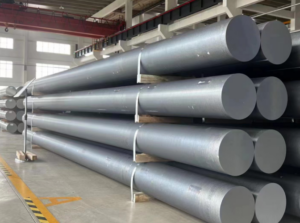

our H13 Tool Steel Supply: Available Forms and Sizes

| Form | Thickness / Diameter | Width | Length |

|---|---|---|---|

| H13 Tool Steel Sheets | 1 mm – 20 mm | 300 mm – 1200 mm | 1000 mm – 3000 mm |

| H13 Tool Steel Plates | 10 mm – 100 mm | 500 mm – 2000 mm | 1000 mm – 6000 mm |

| H13 Tool Steel Round Bars | 10 mm – 500 mm diameter | – | 1000 mm – 6000 mm |

| H13 Tool Steel Flat Bars | 5 mm – 80 mm thickness | 20 mm – 500 mm | 1000 mm – 6000 mm |

| H13 Tool Steel Blocks | Customizable thickness | Customizable | Customizable |

| H13 Tool Steel Square Bars | 10 mm – 200 mm | 10 mm – 200 mm | 1000 mm – 6000 mm |

Notes:

- Custom Sizes: Available upon request based on specific requirements.

- Tolerance: Dimensions may vary according to industry standards and client specifications.

- Heat Treatment: H13 Tool Steel can be supplied in annealed or pre-hardened conditions.

H13 Tool Steel material properties datenblatt as below:

chemical composition of H13 Tool Steel

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.32 – 0.45 |

| Chromium (Cr) | 4.75 – 5.50 |

| Molybdenum (Mo) | 1.10 – 1.75 |

| Vanadium (V) | 0.80 – 1.20 |

| Silicon (Si) | 0.80 – 1.20 |

| Manganese (Mn) | 0.20 – 0.50 |

| Phosphorus (P) | 0.03 max |

| Sulfur (S) | 0.03 max |

Physical Properties of H13 Tool Steel

| Physical Property | Value |

|---|---|

| Density | 7.80 g/cm³ |

| Thermal Expansion | 11.0 x 10⁻⁶ /°C (20-100°C) |

| Thermal Conductivity | 28.6 W/m·K at 20°C |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity | 0.55 x 10⁻⁶ Ω·m |

| Melting Point | 1427°C |

Mechanical Properties of H13 Tool Steel

| Mechanical Property | Value |

|---|---|

| Hardness (Rockwell) | 48 – 52 HRC (after heat treatment) |

| Tensile Strength | Approximately 1,450 MPa |

| Yield Strength | Approximately 1,200 MPa |

| Modulus of Elasticity | 210 GPa |

| Impact Toughness | High (suitable for hot-work applications) |

| Elongation at Break | 10 – 15% (varies with treatment) |

Applications of H13 Tool Steel:

- Die Casting Dies: Suitable for molds exposed to high temperatures.

- Extrusion Dies: Ideal for shaping metals under intense heat.

- Forging Dies: Used in high-impact, high-temperature forging processes.

- Plastic Molds: Effective for plastic injection molds due to thermal stability.

- Hot Shear Blades: Withstands high heat during cutting operations.

Different Designations for H13 Tool Steel:

| Standard | Designation |

|---|---|

| UNS | T20813 |

| AISI/SAE | H13 |

| DIN | 1.2344 |

| JIS | SKD61 |

| ISO | X40CrMoV5-1 |

| BS | BH13 |

| EN | X40CrMoV5-1 |

Fabrication and Heat Treatment of H13 Tool Steel:

Fabrication:

- Machining: H13 is relatively difficult to machine due to its high hardness, but it can be machined in its annealed state. Carbide-tipped tools are often recommended for better tool life.

- Grinding: H13 can be ground to precise dimensions after hardening, commonly used for final finishing.

- Welding: Welding H13 requires preheating to avoid cracking and post-weld heat treatment to restore hardness and toughness.

Heat Treatment:

Annealing:

- Heat slowly to 840-860°C, hold for a uniform soak, then cool at a rate not exceeding 10°C per hour down to 600°C. This process produces a maximum hardness of 229 HB (Brinell Hardness).

Stress Relieving:

- To relieve machining-induced stress, heat to 600-650°C, hold for 1-2 hours, then cool in air. This process minimizes distortion in further heat treatments.

Hardening:

- Preheat H13 to 600-700°C, then raise to 1000-1030°C and hold until uniformly heated. Quench in still air, oil, or pressurized gas for large sections. Air cooling minimizes distortion.

Tempering:

- Temper immediately after hardening by heating to 500-650°C for desired hardness, holding for 2 hours, then air cooling. Typically, H13 is tempered 2-3 times to increase toughness and thermal stability.

Contact us now! Free sample waiting for you.

Tel: +86-13012867759

Email: [email protected]

Tel: +86-021-54725826

Fax: +86-021-54717930