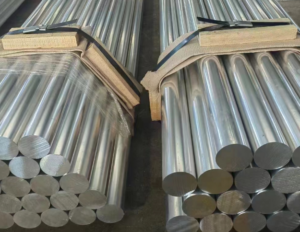

Tool steel, as a crucial category of metallic materials, finds extensive applications in modern manufacturing due to its remarkable strength, hardness, and wear resistance. To ensure that metallic materials possess even more superior comprehensive properties, cold work hardening is employed in the processing and manufacturing of tool steel to enhance its performance. In this article, let’s take a closer look at the cold work hardening of tool steel and its applications.

Cold Work Hardening of Tool Steel and Its Applications:

In metalworking, cold work hardening is a common steel treatment method that involves subjecting metallic materials to plastic deformation at room temperature or below the recrystallization temperature. This process elevates the hardness and strength of the surface layer metal through lattice distortion, shearing, and sliding of grains. The primary cold work hardening techniques used for tool steel include cold rolling and cold forging.

Cold rolling is a rolling process conducted below the recrystallization temperature of steel, including at room temperature. Compared to hot rolling, cold-rolled steel exhibits superior mechanical properties due to its characteristic of cold work hardening. During cold rolling, the crystals of tool steel undergo sliding and dislocation movements during plastic deformation, leading to changes in grain shape and size, as well as an increase in dislocation density. These alterations in the internal structure of the steel contribute to an enhancement in its hardness and strength.

Similarly, cold forging is a forming process performed below the recrystallization temperature, specifically below the recovery temperature. Cold forging strengthens metals and enhances the strength of components. This method is applicable not only to tool steel but also to aluminum and some alloys, copper and some alloys, low-carbon steel, medium-carbon steel, and low-alloy structural steel. Cold forging not only improves the strength, dimensional accuracy, and surface quality of components but also saves material and reduces costs.

In practical applications, cold work hardening is particularly significant as it can increase the strength and corrosion resistance of steel materials without altering their fundamental properties, thereby extending their service life. Consequently, this process is widely utilized in metalworking, automotive manufacturing, aerospace, electronics, and other fields. Furthermore, cold work hardening plays a pivotal role in cold-working tool steels, such as those used for punching dies, cold heading dies, and cold extrusion dies, by fulfilling specific industrial requirements.

Conclusion

In conclusion, cold work hardening is a vital metalworking method that modifies the physical properties of metals, including their hardness and strength. While tool steel subjected to cold work hardening exhibits improved wear resistance and longevity, it also experiences a reduction in plasticity. Therefore, it is crucial to consider this effect during the cold work hardening process to prevent excessive plasticity loss and ensure that tool steel achieves optimal performance.

Why Choose Sino Special Metal?

Thank you for reading our article and we hope it can help you to have a better understanding of the cold work hardening of tool steel and its applications. If you are looking for suppliers and manufacturers of tool steel, we would advise you to visit Sino Special Metal.

As a leading supplier of tool steel from Shanghai China, Sino Special Metal offers customers high-quality D2 Tool Steel(UNS T30402), A2 Tool Steel(UNS T30102), H13 Tool Steel(UNS T20813), M2 Tool Steel(UNS T11302) and O1 Tool Steel(UNS T31501).