High-speed steel, as a crucial type of alloy steel, boasts exceptional red hardness, enabling it to maintain superior cutting performance and durability even under high-speed cutting conditions. This feature meets the rigorous demands for cutting ability and wear resistance in modern industrial production, thereby finding widespread applications in sectors such as aerospace, automotive manufacturing, and engineering machinery. In this article, we will take a closer look at the red hardness of high-speed steel and its significance.

Red Hardness of High-Speed Steel and Its Significance:

The red hardness of high-speed steel plays a pivotal role in its extensive adoption. For instance, during precision machining, this red hardness allows high-speed steel to retain high hardness and strength under extreme cutting temperatures of up to 600°C, effectively resisting deformation and wear. Consequently, it ensures the performance and longevity of cutting tools. Hence, taking necessary measures to enhance the red hardness of high-speed steel is paramount.

Firstly, increasing the content of alloying elements is crucial. The red hardness of high-speed steel is primarily determined by the content of alloying elements such as tungsten, molybdenum, cobalt, and vanadium. These elements form carbides at elevated temperatures, ensuring the steel’s exceptional hardness and maintaining its cutting capability and wear resistance under high-temperature conditions. Additionally, enhancing the content and ratio of these alloying elements within high-speed steel further boosts its hardness even amidst the substantial heat generated during high-speed cutting.

Secondly, adopting advanced manufacturing processes significantly improves the red hardness of high-speed steel. For instance, compared to traditional melting methods, the use of powder metallurgy for high-speed steel avoids carbide segregation issues. Furthermore, techniques like vacuum smelting and rapid solidification lead to a more uniform and finer microstructure, significantly enhancing the steel’s red hardness.

Additionally, optimizing the heat treatment process is essential. By refining heat treatment parameters, including temperature, time, and cooling methods, the microstructure and properties of high-speed steel can be improved. For example, raising the quenching temperature facilitates the dissolution of more carbides into the austenitic matrix, thereby elevating the material’s red hardness. Furthermore, subjecting high-speed steel to liquid nitrogen cryogenic treatment promotes the precipitation of ultra-fine carbides, enhancing its hardness, wear resistance, and impact toughness, further bolstering its red hardness.

Conclusion

In conclusion, the red hardness of high-speed steel serves as a hallmark of its status as a high-performance tool steel, crucial for ensuring efficient and quality machining processes. Practical approaches to enhancing its red hardness, including elevating alloying element content, embracing advanced manufacturing techniques, and optimizing heat treatment processes, effectively improve cutting efficiency and tool longevity.

Why Choose Sino Special Metal?

Thank you for reading our article and we hope it can help you to have a better understanding of the red hardness of high-speed steel and its significance. If you are looking for suppliers and manufacturers of high-speed steel, we would advise you to visit Sino Special Metal.

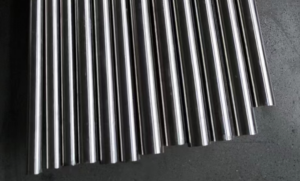

As a leading supplier of high-speed steel from Shanghai China, Sino Special Metal offers customers high-quality high-speed steel products such as M2 High-Speed Steel, M35 High-Speed Steel, and M42 High-Speed Steel at a very competitive price.