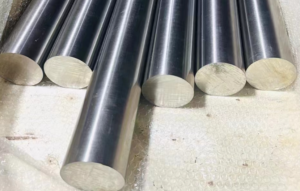

Tool steel is a vital material that is widely used in the manufacture of cutting tools, molds, measuring tools, etc. The purpose of this article is to provide readers with a detailed guide to tool steels, including their types, properties, and main uses, with a view to providing a valuable reference in metal processing and material selection.

Guide to Tool Steels: Types, Properties, and Uses

1. Overview of tool steel

Tool steel is a special steel with high hardness, wear resistance and certain toughness. Its main feature is its ability to maintain stable performance under long-term working conditions. Tool steel can be divided into three categories: carbon tool steel, alloy tool steel and high-speed tool steel according to its chemical composition and heat treatment process.

2. Types of Tool Steel

- Carbon tool steel: Carbon tool steel is the most basic type of tool steel, with a carbon content between 0.65% and 1.35%. After proper heat treatment, the surface of carbon tool steel can obtain higher hardness and wear resistance, and is suitable for manufacturing some tools that do not require high hardness, such as files, scrapers, etc.

- Alloy tool steel: Alloy tool steel is made by adding a certain amount of alloy elements (such as Cr, Mo, V, etc.) to carbon tool steel. These alloying elements can significantly improve the hardness, wear resistance and thermal stability of steel, making it suitable for manufacturing tools with higher requirements, such as punch dies, forging dies, etc. Alloy tool steel can be further subdivided into cold work die steel, hot work die steel, etc. based on its use and performance characteristics.

- High-speed tool steel: High-speed tool steel is a tool steel with high alloy content, containing C, Mn, Si, Cr, V, W, Mo, Co and other elements. High-speed tool steel is known for its excellent hardness, wear resistance and red hardness, and is mainly used to manufacture high-speed cutting tools and heavy-duty molds.

3. Performance of Tool Steel

- Hardness: One of the primary properties of tool steel is hardness. Hardness refers to the ability of a material to resist localized plastic deformation, scratching, or indentation. The hardness of tool steel is usually controlled through heat treatment processes such as quenching and tempering to meet the use requirements of different tools.

- Wear resistance: Wear resistance is another important property of tool steel. In processes such as cutting and stamping, the wear resistance of tool steel determines its service life. Alloying elements and heat treatment processes have a significant impact on the wear resistance of tool steels.

- Red hardness: Red hardness refers to the ability of a material to maintain its hardness at high temperatures. For tool steels that need to work at high temperatures (such as hot work die steel), red hardness is particularly important. High-speed tool steel is widely used in high-speed cutting fields due to its excellent red hardness.

- Toughness: Toughness refers to the ability of a material to resist fracture under impact loading. Tool steel needs to take into account its toughness requirements during the manufacturing process to ensure that it does not break or fail under complex working conditions.

4. Uses of tool steel

- Cutting tools: Cutting tools are one of the main application areas of tool steel. High-speed tool steel has become the preferred material for manufacturing cutting tools due to its excellent hardness and wear resistance. Carbon tool steel and alloy tool steel are also widely used in the manufacture of various cutting tools.

- Mold: Molds are another important application area for tool steel. Cold work die steel and hot work die steel are used to manufacture molds such as cold stamping dies and hot forging dies respectively. These molds play a vital role in metal processing and have high requirements on the hardness, wear resistance and red hardness of the tools.

- Measuring tools: Measuring tools are tools used for measurement and inspection, which have extremely high requirements for accuracy and stability. After precision processing, carbon tool steel and alloy tool steel can be used to make measuring tools such as rulers and calipers.

- Other tools: In addition to the above application fields, tool steel can also be used to manufacture various wear-resistant tools and special-purpose tools, such as rolls, wire drawing dies, etc.

Conclusion

Thank you for reading our article and we hope this guide to tool steels can be helpful to you. If you are looking for tool steel suppliers and manufacturers online now, we would advise you to visit Sino Special Metal for more information.

As a leading supplier of tool steels from Shanghai China, Sino Special Metal offers customers high-quality tool steel products at a very competitive price.