Suspension spring steel is one of the main components of the automobile suspension system. During the driving of the car, the suspension spring steel plays a buffering and shock-absorbing role, and its quality directly affects the performance and service life of the car. The production of high-grade suspension spring steel requires the following processes.

Analysis of production process of automobile suspension spring steel:

- In terms of material selection, automobile suspension springs often undergo high-frequency reciprocating compression movements, which requires spring steel to have good elasticity and fatigue resistance. Therefore, suspension springs generally use high-strength materials, such as 55SiCr spring steel commonly used in automobiles.

- In smelting and processing, in order to ensure the uniformity and stability of suspension spring steel, it is necessary to reduce the content of O, P, and S elements in the steel to improve the purity of the steel. During the smelting process, special smelting processes need to be used for refining treatment, such as RH process or VD process.

- Heat treatment: Automobile suspension springs need to have extremely high tensile strength. Quenching and tempering of spring steel can not only improve the hardness and strength of the steel, but also improve its toughness and plasticity. Therefore, heat treatment is crucial to the performance of suspension spring steel.

- Surface treatment: Suspension spring steel often works under complex environmental conditions, requiring the steel to have a long service life. Shot blasting, painting and other treatments on the surface of spring steel can not only prevent corrosion, but also improve its wear resistance and fatigue strength.

- Special treatments, such as ultra-low oxygen technology, use aluminum deoxidation and high alkalinity refining slag to reduce the oxygen content in the steel, reduce the number of inclusions, and improve the performance of suspension spring steel. For suspension spring steel with extremely high performance requirements, some special processing is essential.

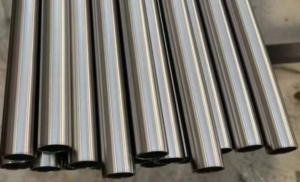

- Cold working. In order to obtain the appropriate type of automobile suspension spring steel, it is essential to cold work the spring steel, including drawing, cutting, etc. Through these processes, the required spring steel wire shape and size can be formed.

Conclusion

To sum up, every step of the production process has an important impact on the performance of suspension spring steel. Precise control of each link in the production process can ensure that the suspension spring steel has excellent performance and meets the needs of the automotive suspension system.

Thank you for reading our article and we hope you’ve enjoyed it. If you are looking for spirng steel suppliers and manufacturers online now, we would advise you to visit Sino Special Metal for more information.

As a leading supplier of spring steel from Shanghai China, Sino Special Metal offers customers high-quality spring steel products at a very competitive price.